Case Study: Emergent 10GigE High-Speed Cameras Aid in Wind Tunnel Testing

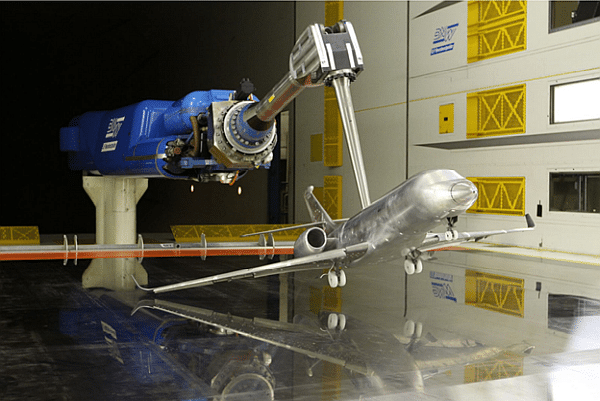

German-Dutch Wind Tunnels (DNW) – one of the leading wind tunnel service providers in the world – operates six wind tunnels located in Germany and the Netherlands. By placing aircraft, vehicle, building, or other solid models in an airstream of known velocity, wind tunnels allow researchers to investigate air flow around objects or the effect of wind on objects DNW operates one of Europe’s largest wind tunnels and provides experimental simulation solutions for aerodynamic research and development projects from academia, the aeronautical industry, as well as automotive, civil engineering, shipbuilding, sports, and other industries.

A key capability for DNW is extracting as much high-quality data from a wind tunnel test as possible. To increase the quality and cost-effectiveness of its services, DNW continuously deploys cutting edge measurement techniques and analysis of test results. The company often uses techniques for measuring surface pressures, forces, velocity, and noise. Aircraft performance relies on a precise knowledge of the exact propeller, rotor blade and wing geometry.

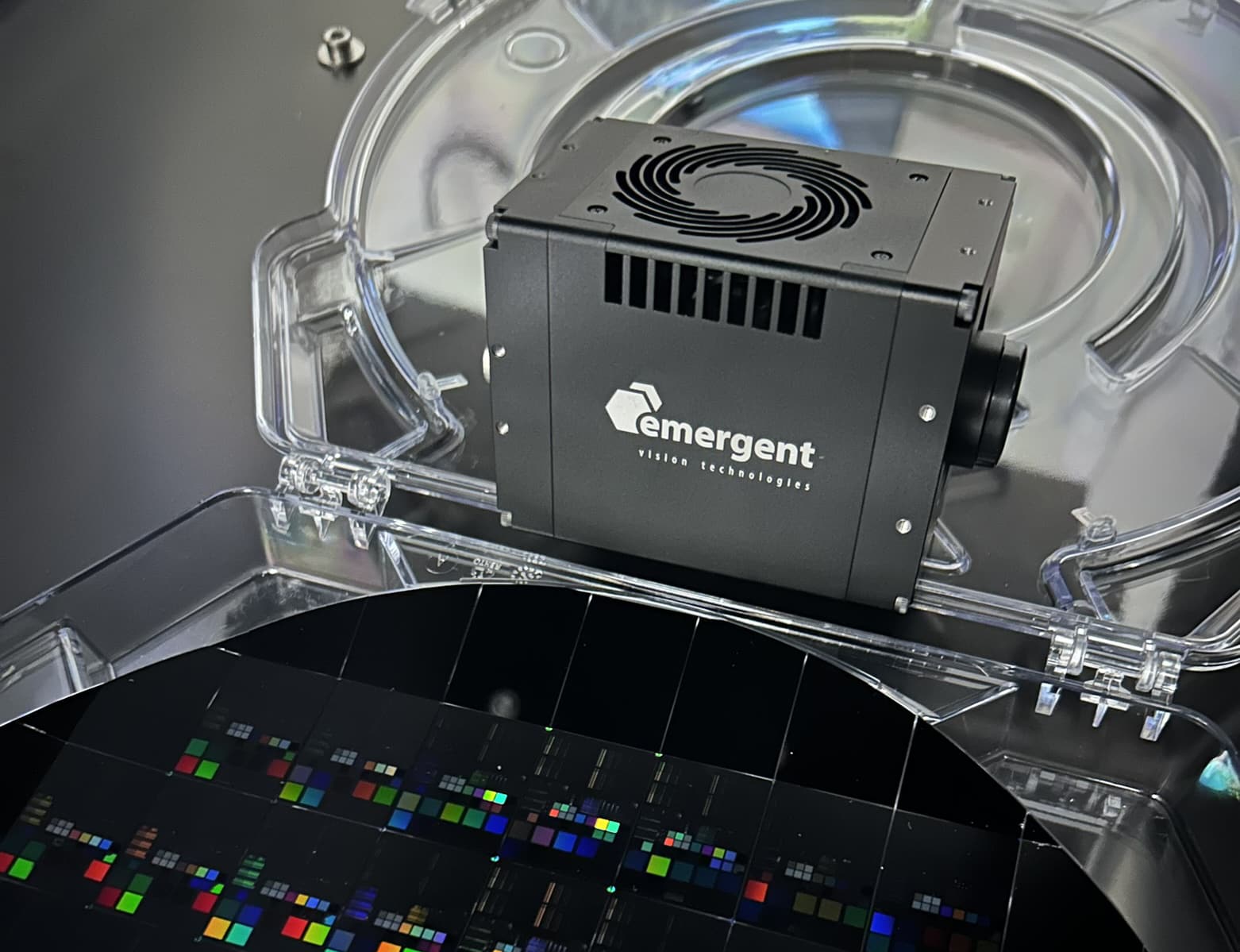

Under the various wind loads that occur from takeoff through landing, the wind tunnel model parts deform resulting in wing bending and twisting. To measure such model deformation, DNW developed a stereoscopic point tracking system that simultaneously tracks markers from different angles during wind tunnel tests. As part of this system, DNW uses 20MP 10GigE HR-20000 cameras from Emergent Vision Technologies to monitor the wind tunnel model equipped with nonintrusive markers. Learn more about how these cameras enabled wing and flap deformation in the new High-Speed Cameras Aid Wing Deformation Measurement Test in Wind Tunnels case study.